eWheel - Overview

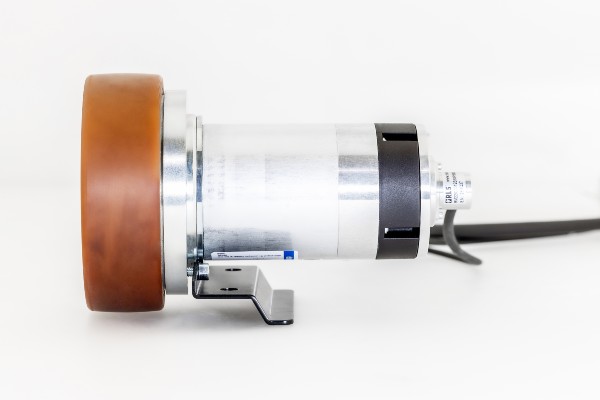

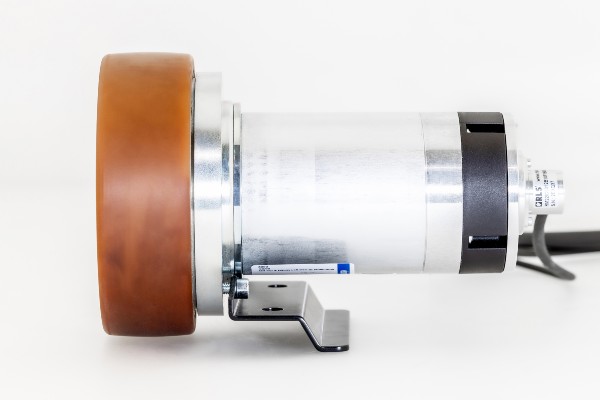

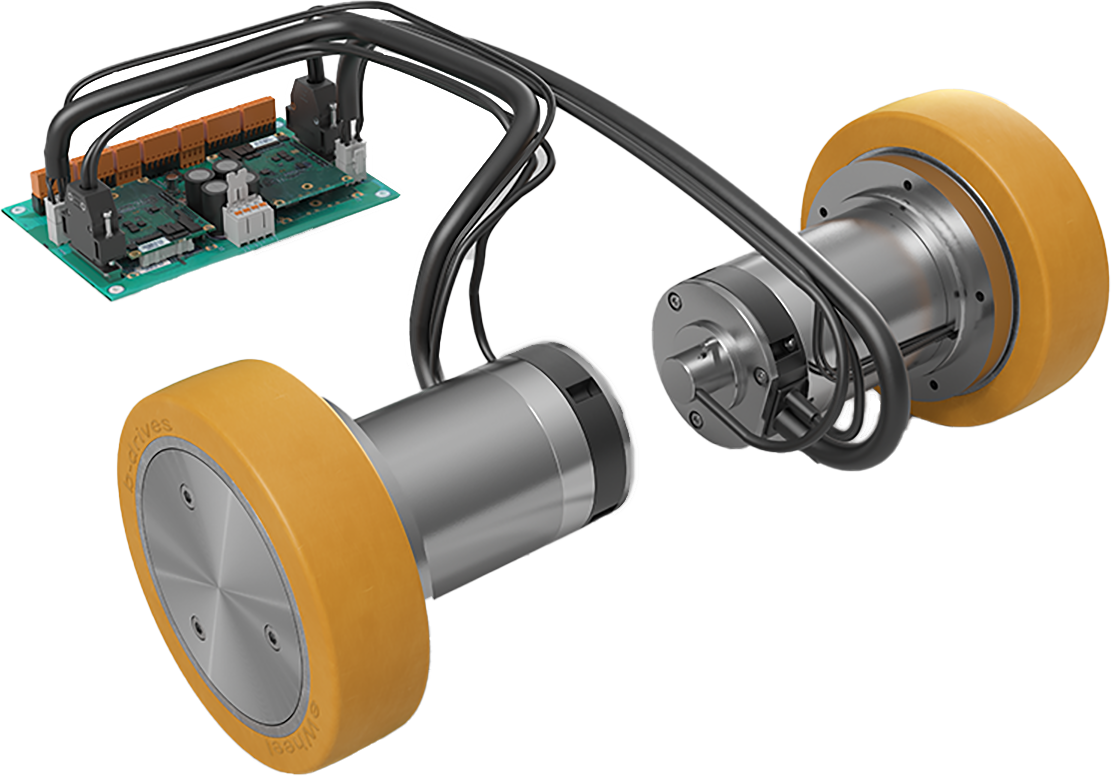

The eWheel from b-drives transports large loads safely and autonomously in confined spaces. As the most compact wheel drive system on the market, it adapts effortlessly to your design requirements. Despite its compactness, eWheel offers impressive power density and high efficiency, maximising vehicle uptime.

BLDC motor with redundant encoder equipment ensures a safe drive, and the overload capacity is evident when accelerating and travelling uphill.

Product information

| eWheel | Unit | S | M | L | XL |

|---|---|---|---|---|---|

| Construction length | mm | 109 | 199 | 219 | 238 |

| Maximum speed | m/s | 0,7-3,0 | 1,0-3,7 | ||

| Maximum torque | Nm | 29-90 | 21-54 | 35-90 | 35-100 |

| Nominal voltage | V | 24/48 | 48 | ||

| Motor protection class | IP00 | IP54 | |||

| Wheel protection class | IP69 | ||||

| Wheel diameter | mm | 140/160/200 | |||

| Parking brake with emergency stop function (motor) | Nm | 1-3 | |||

| Redundant feedback with Hall sensors and incremental encoder | ✓ | ||||

| Payload per wheel | kg | 500kg | |||

| Wheel material | Vulkollan® 92° Shore A | ||||

| Options | |||||

| Functional safety STO PL e | ✓ | ||||

| Safety encoder attachment | x | ✓ | |||

| Application-specific wheel surface | ✓ | ||||

| Attachment to the vehicle | from the vehicle exterior/interior or above the drive using a mounting bracket |

||||

Product options

Our eWheel offers you full flexibility. In addition to the gearbox and motor

- drive control,

- wheel covering,

- mounting flange

- and brake

vary.

We can also support you with your individual requirements in functional safety.

Simply contact us for a consultation appointment!

Wheel covering

Our standard wheel lining is made of Vulkollan® with a hardness of 92° shore A. However, wheel coverings made of Vulkollan® 70° Shore A or other crowns are also conceivable and possible. Vulkollan® is a polyurethane traded by Covestro AG. Other materials and Shore hardnesses that have proven themselves in intralogistics are also possible.

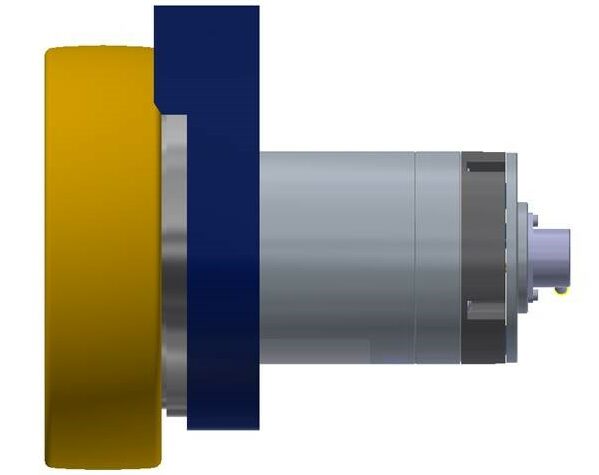

Mounting flange

With our eWheel, we offer the options that you can mount it either from the outside or from the inside of the vehicle itself. This type of mounting is always given and is part of our standard programme.

You make the selection of the mounting direction, whether you want to screw on the eWheel from the outside or from the inside. On this basis, we then select the appropriate mounting flange in production.

In addition, we can also offer you a standardised mounting bracket for our eWheel in order to conveniently attach it under your vehicle chassis. In this way, you can simply screw the AGV on above our eWheel.

Drive controller

Our dual-axis controller has STO (Safe Torque Off) according to PL e and can therefore be a component of your functional safety concept for your AGV. The controller is voltage-resistant up to 60V with a peak current of 60A. Our standard interface of the double-axis controller is CANopen. You therefore need one dual-axis controller per AGV for two eWheels.

Functional safety

In normal operation, the eWheel's BLDC motor brakes generatively, feeding energy back into the battery or to other consumers. For safety-oriented emergency braking, the eWheel has a mechanical holding brake with emergency stop function.

The gearbox amplifies the braking torque accordingly, so that the vehicle comes to a safe standstill even in unfavourable operating situations. We can adapt the nominal braking torque to your application.

For functional safety on the electronic side, the eWheel offers the following options:

Solution with STO

The double-axis drive controller has STO according to PL e. This means that the torque of two drives can be switched off via a safe channel (for example from a safe PLC). Of course, it is possible to trigger the holding brakes together with the STO.

Redundant encoder system for SLS and SDI

The motors each have two independent encoder systems as standard:

- Hall sensors for commutation

- High-resolution incremental encoder for control.

By balancing both signals with appropriate electronics, the speed can be reliably recorded in functional terms.

Solution with SLS and SDI through safe encoder

As a further option, we offer the attachment of a safe encoder to the eWheel. The possible designs are sin/cos encoders, TTL or HTL incremental encoders. These signals can be evaluated in corresponding modules of the safety controls.

Solution with SLS and SDI with Siemens MicroDrive PDC

Optionally, the eWheel can be equipped with motors that are compatible with the MicroDrive PDC from Siemens. By using the PDC-F series from Siemens, a variety of safety functions are automatically available via PROFIsafe.

Here you can download our current product brochure for our wheel drive. In it you will find detailed information on our flexible modular system, both general and technical information on the individual versions. If you do not see your requirements illustrated, please do not hesitate to contact us!

Flyer - Wheel drive for automated guided vehicles (AGVs)

b-drives® eWheel